Clogged plumbing pipes

Commercial properties can have unique storm and wastewater drainage design features and plumbing devices. Most of these features and devices are installed in buildings to protect the watershed or municipal systems from contamination by certain substances and to prevent sewer blockages and damage to plumbing systems.

Businesses requiring these features and devices include restaurants, car washes, machine shops, car dealers, buildings with bays or floor drains, service stations, fueling facilities, businesses that use steam equipment, and “quick lube” auto shops.

The main types of equipment that commercial property inspectors will come across include oil-water separators (OWS), grease traps, grease inceptors, and triple basins. The removal of the covers and the determination of operation of these devices is beyond the visual nature and scope of a walk-through survey. Still, it is important to understand their function and purpose.

Oil-Water Separator (OWS)

An oil-water separator is installed at properties that generate oily wastewater from the use of petroleum products. Standard baffle OWS are large-capacity, underground cement vaults installed between a drain and the connecting sewer pipe. These vaults are designed with baffles to trap sediments and retain floating oils. The large capacity of the vaults slows down the wastewater, allowing oil to float to the surface and solid material to settle out.

Another popular design is the coalescing plate separator (CPS), which can be installed above or below ground. It has a smaller capacity and employs a series of oil-attracting plates. Oil droplets collect and float to the surface, where they can be skimmed off or removed mechanically.

Inspectors may find OWS at “quick lube” shops, transportation fueling facilities, vehicle/heavy equipment yards, and car washes and other businesses that use steam or pressure washers. These are complex devices that require attention from firms specializing pumping out and cleaning OWS systems, such as tank cleaning servicers.

Grease Trap

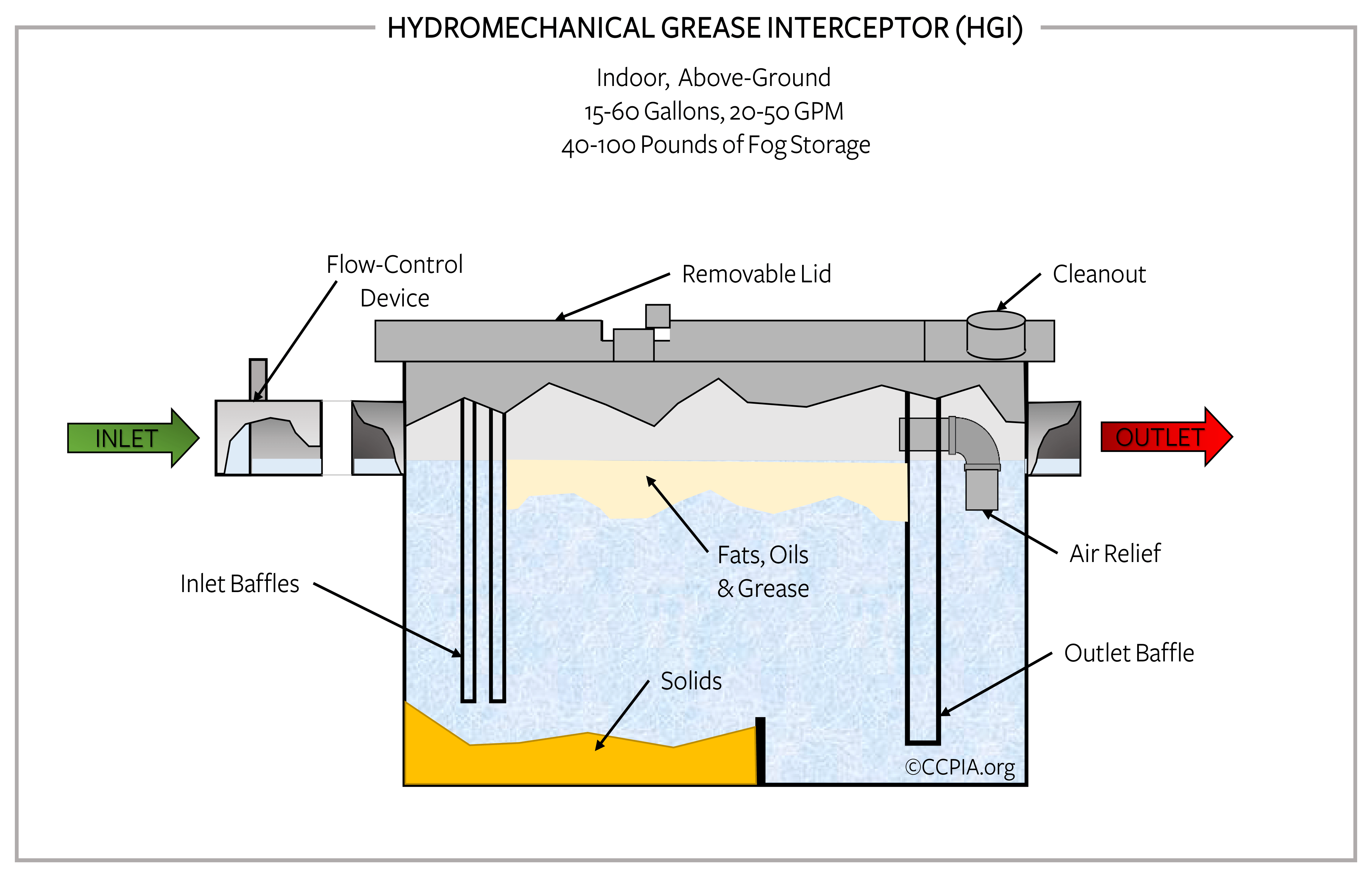

The terms “grease trap” and “grease interceptors” are often used interchangeably, but they are distinctly different technologies that are found at food-handling establishments. Another term for a grease trap is hydromechanical grease interceptor (HGI). While both “grease trap” and “grease interceptors” remove fats, oils, and grease (FOG) from water and operate by similar principles, grease traps are installed indoors and near the locations where grease is generated, such as under two- or three-compartment sinks, and near dishwashers, pot sinks, and mop sinks. Grease traps are typically monitored and cleaned by restaurant employees and require no special equipment to clean.

The majority of grease traps are passive, which means that they operate without any moving or mechanical parts. Greasy wastewater entering the trap passes through a vented flow control that regulates the flow of the wastewater. The wastewater passes over a series of baffles that separate the grease and oil from the water by slowing the flow to allow enough detention time for lighter fats, oils, and greases to rise. The clean water rests at the bottom, where it may leave the unit through an exit valve, retaining the FOG within the trap until it is cleaned out.

Hydromechanical Grease Inceptor (also commonly referred to as grease trap)

The use of adequately sized and regularly inspected grease traps is mandated by local jurisdictions in places that routinely generate significant amounts of grease that would otherwise wind up in public sewers. Proper installation and maintenance prevent potential damage to privately owned plumbing systems and public waterworks systems, as well as costly repairs.

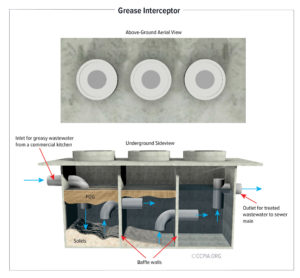

Grease Interceptor

Unlike the smaller industrial grease trap, a grease interceptor is a large underground concrete box with two or three compartments (some having a capacity of several thousand gallons) that typically serve high-flow applications, such as larger restaurants, hotels, factories, and grocery stores. The grease interceptor is typically located between the kitchen drain lines and the sanitary sewer lines outside the establishment under one, two, or three manhole covers. Grease interceptors work essentially the same way as grease traps, but on a larger scale. Grease interceptors also require periodic maintenance by professionals.

Triple Basin

Another common form of contaminant control is called a triple basin. This is commonly placed against a wall and adjacent to a floor or drain structure. This floor drain structure could be as large as a two-foot catch basin lid, or as small as a typical floor drain, or it could be a long slot drain. The purpose of this system is to capture contaminated water and place it into this vessel.

Within this vessel are three chambers. The lids of the three chambers are visible on the floor. The chambers remove the heavy particulate, floating debris, and hydrocarbons from the stormwater before it can migrate into the main drain system and out from the building.

Stormwater enters the first chamber where the heaviest solids and sediments drop to the bottom of the chamber. The water flows to the second chamber where oils and grease can be removed and additional suspended solids settle. Oils and grease are stored in the second chamber and can be pumped out or removed during periodic maintenance. In the third chamber, the clarified stormwater is then discharged slowly to allow additional settlement, and then ultimately discharged into the stormwater system. These systems work very effectively but, depending on the amount of use, will require periodic monitoring and cleaning.

Depending on the size of the building, several of these may be installed. The commercial inspection should include identifying the presence of the triple basin, locating the proper venting (which should extend through the roof), and identifying any visual issues with the covers or other exposed components.

Automatic Grease Removal System

Automatic grease-removal system

Grease traps and interceptors merely trap grease, so they should not be confused with automatic grease-removal units or grease converters. The former device employs hydrostatic pressure or a skimmer to clean itself, has more moving parts, and relies on motors, heaters and timers. Grease converters trap grease in a tank that contains bacteria and enzymes that digest the grease and convert it into a water-soluble, biodegradable product that can be safely discharged into the drainage system.

Takeaway for Commercial Property Inspectors

Businesses that generate oily and greasy wastewater have unique design features and plumbing devices that protect the watershed or municipal system from contamination. The plumbing devices include OWS, grease traps, grease interceptors, triple basins, and automatic grease removal systems in various designs and setups. Commercial property inspectors do not need to remove covers or operate these systems. The removal of the covers or determination of their operation is beyond the visual nature and scope of the walk-through inspection, but it is important to understand the function and purpose of these two systems. It may also behoove the inspector to advise their clients of the importance of proper maintenance of the plumbing systems and devices to prevent costly repairs from potential buildups and blockages.

Article By Rob Claus, CMI® and Maggie Aey

Additional Resources for Commercial Property Inspectors: