Many commercial building inspections include some sort of kitchen. Some kitchens are similar to those found in homes, while others are much more complex in terms of size and system components. Understanding the technical components of a commercial kitchen exhaust hood will help the commercial inspector better identify defects and work with specialty consultants or contractors assisting during the inspection.

First, the inspector may be able to determine what kind of kitchen will be present before the walk-through survey based on the building type.

For instance, an office building or unit may have a small break room, which will likely have the same features and systems as a kitchen found in a home. Therefore, the observations and inspection requirements should be similar, if not the same. In this case, a commercial kitchen exhaust hood will not be present.

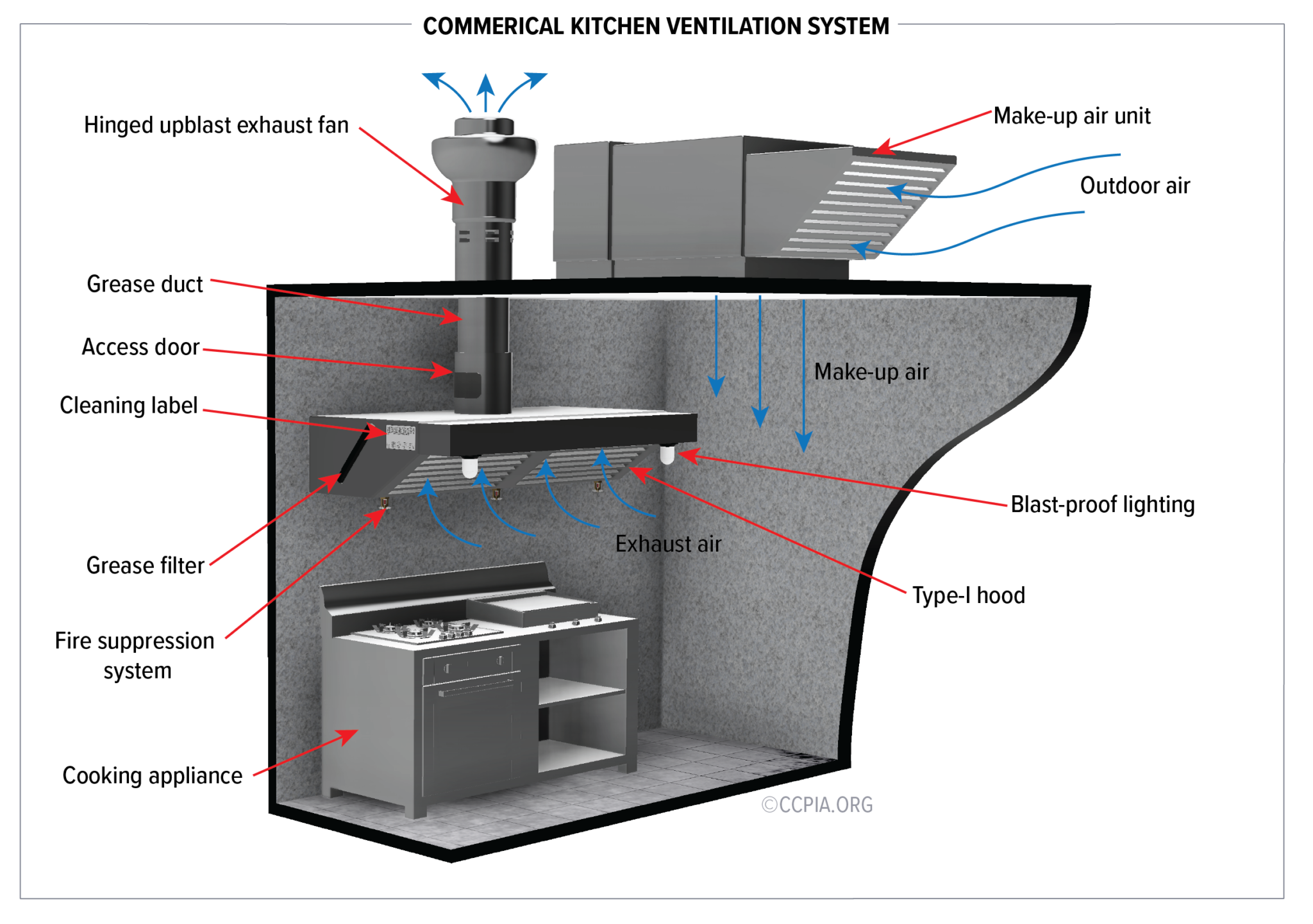

A typical commercial kitchen is commonly present in hotels and restaurants. It is much more complex, and a commercial kitchen exhaust hood will be present. Depending on the inspector’s experience and the scope of the inspection, a specialty consultant or contractor may be required to assist the inspector. Since commercial kitchen exhaust hoods are one the most visible components in a commercial kitchen’s ventilation system, the difference between the two kitchen styles should be obvious.

The exhaust hood is the primary filtration system at a commercial kitchen, so it is important that it is functioning properly. In general, the purpose of an exhaust hood is to capture heat, steam, airborne grease, combustion products, and other effluents leaving the surface of the cooking appliance. There are various nationally recognized codes and standards for installing exhaust hoods, and although a commercial property inspector is not required to memorize them, it may be helpful to have a basic understanding and be familiar with a few of them.

For instance, the NFPA 96 of the National Fire Protection Association is a set of codes and standards for ventilation control and fire protection of commercial cooking operations. While the International Mechanical Code (IMC), developed by the International Code Council (ICC), is a set of codes and standards for the design, construction and installation of commercial kitchen systems, this code doesn’t cover the maintenance requirements of exhaust systems, but it references the International Fire Code, which does. However, many codes and standards in state and local jurisdictions in the U.S. and Canada may differ for commercial kitchens.

Before inspecting or reporting on a commercial kitchen, commercial property inspectors should check with their insurance company about coverage. It is common for insurance coverage to exclude coverage for commercial kitchens.

There are two types of commercial kitchen exhaust hoods:

Type I Hoods

Type I hoods, also known as grease hoods, are designed to remove heat, smoke, condensation, and other grease byproducts of cooking. Commercial building inspectors will find these hoods above cooktops, deep fryers, griddles, woks, charboilers, and open-flame stoves. Type 1 hoods must be installed and maintained to meet the minimum requirements of the ICC and NFPA 96 standards.

Type I hoods contain a baffle filter that has two roll-formed baffles equally spaced apart. Baffle filters separate grease from cooking vapors and capture grease inside, while air escapes into the ductwork to the exterior of the building. The captured grease then drains down the angled baffles into a collection trough. Type I hoods require regular cleaning in order to prevent grease fires.

Commercial building inspectors should also be aware that there are two kinds of Type I hoods: listed and unlisted. In general, an unlisted hood must meet the criteria of applicable national and local codes, and fire-actuated dampers are not permitted, while listed hoods are constructed and should be installed according to the manufacturer’s recommendations. This kind of hood will contain a permanent tag that defines related performance criteria. It may contain dampers. All Type I hoods contain baffle filters, modular extractors, and filtration or cyclic water wash systems.

Type II Hoods

Type II hoods, also referred to as condensate hoods, are installed above non-grease-producing appliances and capture dry heat, moisture, and odors, which go through a mesh filter before being incorporated into the HVAC system or a separate removal system. Type II hoods are not permitted above any grease-producing appliance. Commercial building inspectors will typically find these hoods installed above commercial dishwashers, ovens, and pasta cookers. Type II hoods do not adhere to the NFPA 96 Standard.

If a Type II hood is installed over a grease-producing appliance, it is considered non-compliant. This is one of the most dangerous fire hazards in commercial kitchens. An inspector’s ability to identify these types of hoods is critical to fire safety. In many cases, Type II hoods are installed over grease-producing appliances because they are less expensive. During a remodel, a steam-producing appliance might be replaced by grease-cooking equipment originally installed under a Type II hood. A conveyor pizza oven might technically be non-grease producing, yet grease-producing foods will be cooked on them. A commercial inspector may want to include questions concerning the type of food cooked on certain appliances or inquire about any recent building remodels in the Pre-Inspection Questionnaire.

For the purpose of identifying the type of exhaust hood in a commercial kitchen, many state and local jurisdictions require Type II hoods to have a permanent, visible label identifying it as a Type II hood. Additionally, many Type II hoods contain a mesh filter, also known as a honeycomb filter. However, some Type II hoods will contain baffles to prevent the condensate from dripping onto the surface below. Instead of having grease filters, Type II hoods feature a duct collar that helps exhaust the hot, moist air.

Commercial Building Inspection Process

Once a commercial inspector is able to identify the type of commercial kitchen exhaust hood present, he or she will be able to approach the inspection instinctively. The first and one of the most noticeable elements of a commercial exhaust hood is the cleaning and inspection tag, also known as the exhaust cleaning certificate. This tag identifies the last time the hood was professionally cleaned and serviced, and is typically placed on the exterior of the hood. All hoods should be professionally cleaned at least once a year. This includes the ductwork through the roof and/or sidewalls.

The photo at right is from an inspection performed in August 2018. The tag states that the last cleaning was performed in July of 2017. Therefore, this system was ready, if not overdue, for a cleaning. The visual inspection of the system found not only the date to be overdue, but there was a great deal of grease and food residue throughout the roof vents and on the roof surface, which can be seen in the image under the Fan section of this article.

Many kitchens are in service or operating during the time of the walk-through. If this is the case, a commercial inspector can typically ask the kitchen staff to operate the system. The system may already be operating as the walk-through is performed, but if it isn’t, there will be a simple switch or series of switches to turn on the system. However, operating the system is not required and generally outside the scope of the commercial inspection.

A visual inspection of the rest of the system should include assessing the general condition of the filters, determining whether there is a fire-suppression system present, identifying the lighting, noting the location and condition of the makeup air system, and evaluating the exhaust fan and ducting.

Exhaust Hood Filters

The average commercial inspector is not going to remove the filters from the exhaust hood system. Simply noting the presence and the visual condition should be sufficient for most clients. However, if a cook staffer is near, the inspector may want to ask them to remove the filter and, with a flashlight, check the plenum chamber and duct for any type of buildup.

The inspector should first determine whether the hood’s exhaust filter is compliant. Baffle filters should only be installed above appliances that produce grease, while mesh filters should only be installed if the appliance filters capture dry heat, moisture, and/or odors.

Inspection points for filters include:

- Is there excessive grease buildup?

- Is the filter installed correctly, or is it bent and damaged?

- Are the baffles on a baffle filter evenly spaced?

- Are any baffles missing from the filter?

- The bars of baffle filters should run vertically. Do they?

- Is the filter easily accessible and removable for cleaning?

- Baffle filters should be installed at an angle no less than 45 degrees from the cooktop. Is it?

- Is there proper storage of fuel or combustibles near the exhaust system, such as paper products?

Baffle-style filter correctly placed in racks.

Incorrectly installed baffle filters. Baffle filters should be installed vertically in order to drain grease.

Type I hoods require a grease catchment system. The photo below shows a grease catch box. Alternatively, if a grease box isn’t visible, grease may drop the lower troughs of the hood into removable cartridges. This type of system also captures any of the liquid dripping down. Grease catchment systems should be cleaned daily. The number and type of grease catches installed will differ based on the model of hood.

Water Wash System

Water Wash System

A water wash system is only found in Type I hoods. This is an automatic washing system that cleans the filters, UV lamps, and the exhaust plenum. The wash cycle can be operated manually or programmed for automatic self-washing. Water wash systems are also designed to both control and contain fires by activating their water wash and damper system during a fire situation.

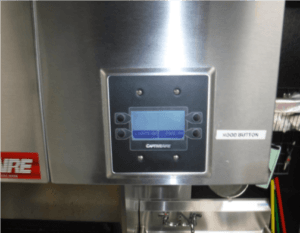

The wash controls and parts are typically stored within a control cabinet inside the kitchen. Information on the service records should be located there as well. Many water wash systems do not receive regular mechanical servicing, which causes the baffles and troughs to accumulate excessive and potentially dangerous amounts of grease. Commercial inspectors should check the water wash system servicing date or ask the kitchen staff or property manager for these records during the research portion of the inspection.

A commercial property inspector isn’t required to operate the water wash system. However, the inspector should check for any sign that the system isn’t running properly.

Questions and items for the inspection of the water wash system include:

- Is there a manufacturer’s service sheet in the control cabinet? Check the last date that the system was serviced. Systems should be serviced about every six months.

- Is there any buildup on any of the pipes or connections in the control cabinet?

- Is there grease buildup in the exhaust hood’s trough or grease catchment box?

- Check the pumps, tubing and pipe fittings for visible signs of leaks.

Fire Extinguishing System

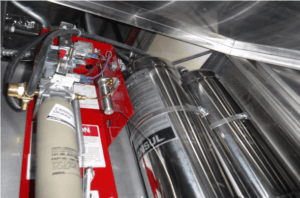

The inspection of fire extinguishing systems, also known as fire-suppression systems, is typically outside of the scope of work for a commercial inspection. Regardless, noting their presence is always recommended. The entire space under the hood should be served by some form of fire-suppression system. This is typically achieved by drop-down tubes from the top of the hood. Never attempt to activate the system. The inspection is truly just visual only and an inventory of the components present in the system, as well as visible defects.

Drop-down nozzles

Canisters for the system

Water wash systems, fire-suppression systems, and their companion controls are complicated pieces of machinery. A service technician will be able to provide more details. The commercial inspector may want to have one attend the commercial kitchen portion of the inspection.

Some basic fire extinguishing inspection questions and items include:

- Is the fire system clean?

- Are the nozzles positioned properly?

- Are the nozzles accessible?

- If the fire extinguishing system nozzles are located in the plenum or opening of the ducts, check for nozzle protective caps. If the caps are missing, they need to be replaced.

- Are piping and tubing continuous (no breaks or missing parts)?

- Check the fire extinguishing system tag for the last date inspected. This is typically located on the manual pull station.

- Check the location of the manual release for the fire extinguishing system for any obstructions.

Exhaust Hood Dampers

Hood dampers can be found in Type I listed hood designs. The hood damper is located in the throat of the hood just before the duct, or within the hood assembly. In a fire situation, the damper will close and prevent the fire from entering the ductwork. The inspection of hood dampers and their components requires advance knowledge of the type of hood and extinguishing system. If a client is interested in these components, the commercial inspector should hire a specialist. However, if the hood damper is visible, the commercial inspector should check for any grease buildup on or behind the damper.

Exhaust Hood Lighting

Lighting should be installed in the hood cavity. Without adequate lighting, it will be very difficult to see what is being prepared under the hood. This lighting has a very distinct design characteristic. It has to be placed in an explosion-proof or flash-proof fixture to prevent any electrical shorts or issues from causing a grease fire in the system.

Testing the lighting can be as simple and activating a switch. This switch may be located on the wall or be a part of the fan-control module. Some moderate searching may be necessary to locate the control. Any use of a standard incandescent bulb without protection should be noted.

Exterior of Commercial Building

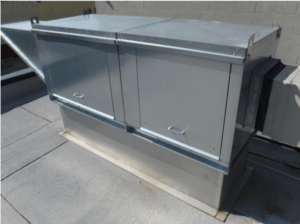

Make-Up Air Fan

The commercial kitchen can create a very difficult work environment. The heat from the various appliances, the fumes and odors from the food being prepared, and gases expelled from burning of the fuel used to operate the appliances can all attribute to poor air quality. Many kitchens are equipped with some form of fresh-air input system. This is usually attached to the exhaust system and will cycle fresh air into the exhaust whenever the system is in operation. If the kitchen is located in a cold climate, this fresh-air intake may have a heater installed in it.

The type of fresh-air intake pictured at left is typically installed on the roof of the building. It has a metal filter where fresh air is brought into the system and ductwork leading into the hood. It is important to inspect the ductwork. Any damage or openings can result in a failure of the system. Water intrusion and contaminants could be allowed to enter the ducting.

Heating element

Blower motor

Unless the exhaust fan is directly installed on the hood, there will be a duct system present. Like the fresh-air intake, the ducts should be inspected for damage, open seams, poor support, or poor slope.

Exhaust Fan

In most cases, the exhaust fan will be located on the roof of the building. However, the inspector may come across an exhaust fan installed on a side wall of the building. There are also various types of fans available for exhausting the hot and contaminated air produced by cooking appliances. This section reviews the most common types, along with their components, and the items to look for during the inspection.

General inspection points for exhaust fans include:

- Fans must be designed to direct air away from the building to prevent roof and building damage.

- Drains and collectors must be used to catch and contain grease that may collect and drip from the fan.

The photo below is a non-compliant down-blast fan. Grease has been expelled onto the roof. A down-blast fan should never be used to expel air from cooking appliances.

An up-blast fan is the most common type of fan installed over commercial kitchen hood exhaust systems, but these fans are also used for other industrial applications for air movement. Generally, the fan used over a commercial kitchen exhaust will be listed for that specific purpose.

The fan unit should have a cover present at the top. This cover prevents the elements from coming directly into contact with any of the interior portions of the fan unit. If rain, ice, snow or any type of water is allowed to enter the system, it can mix with the grease to create a slurry or buildup, and this can cause the system to fail.

In the photos above, note the grease dripping from the exhaust hood and running to the scupper on the TPO roofing surface. This exhaust fan should have a grease catchment box or drain system. As a point of caution, the commercial inspector should be very careful when walking this type of roof. Any grease present can make it extremely slippery.

Inspection points of the fan include:

- Is there a shutoff switch at or near the fan?

- Is the roof protected from grease?

- Is the grease catchment box clean?

- Does the fan have a lid?

Over-full grease catchment box

Conclusion

The commercial property inspector’s ability to identify the various components of the commercial kitchen exhaust system and note any system deficiencies are critical to fire safety, as well as the comfort and health of those working in the kitchen.

There a multiple types of commercial kitchen hoods, and many exhaust system components. Issues with the system can typically be found through the inspection and the information found on service tags. Additionally, being familiar with the various systems and their applications is useful for performing the inspection and composing the report.

Depending the scope of the inspection, the complexity of the system, and the experience of the commercial property inspector, he or she may want to hire a specialty consultant to assist during the inspection, such as a commercial kitchen exhaust technician or a fire safety inspector. Additionally, the inspector should take many photos of the system, and defer to an expert for further review.