Introduction

Bowstring trusses are a distinctive architectural element that can add elegance and character to a building’s design. This style of truss features a horizontal bottom with a swooping arched top. The swooping arch is most often the design of the roof. The swooping arch provides a sloped plane to divert water and create a wide span across the interior of the building. However, like any structural component, bowstring trusses are subject to wear and tear and can potentially fail over time. Regular inspections and maintenance are crucial to ensure the safety and longevity of a building featuring bowstring trusses. Let’s explore the importance of inspecting these trusses, common failures, and best practices for maintenance.

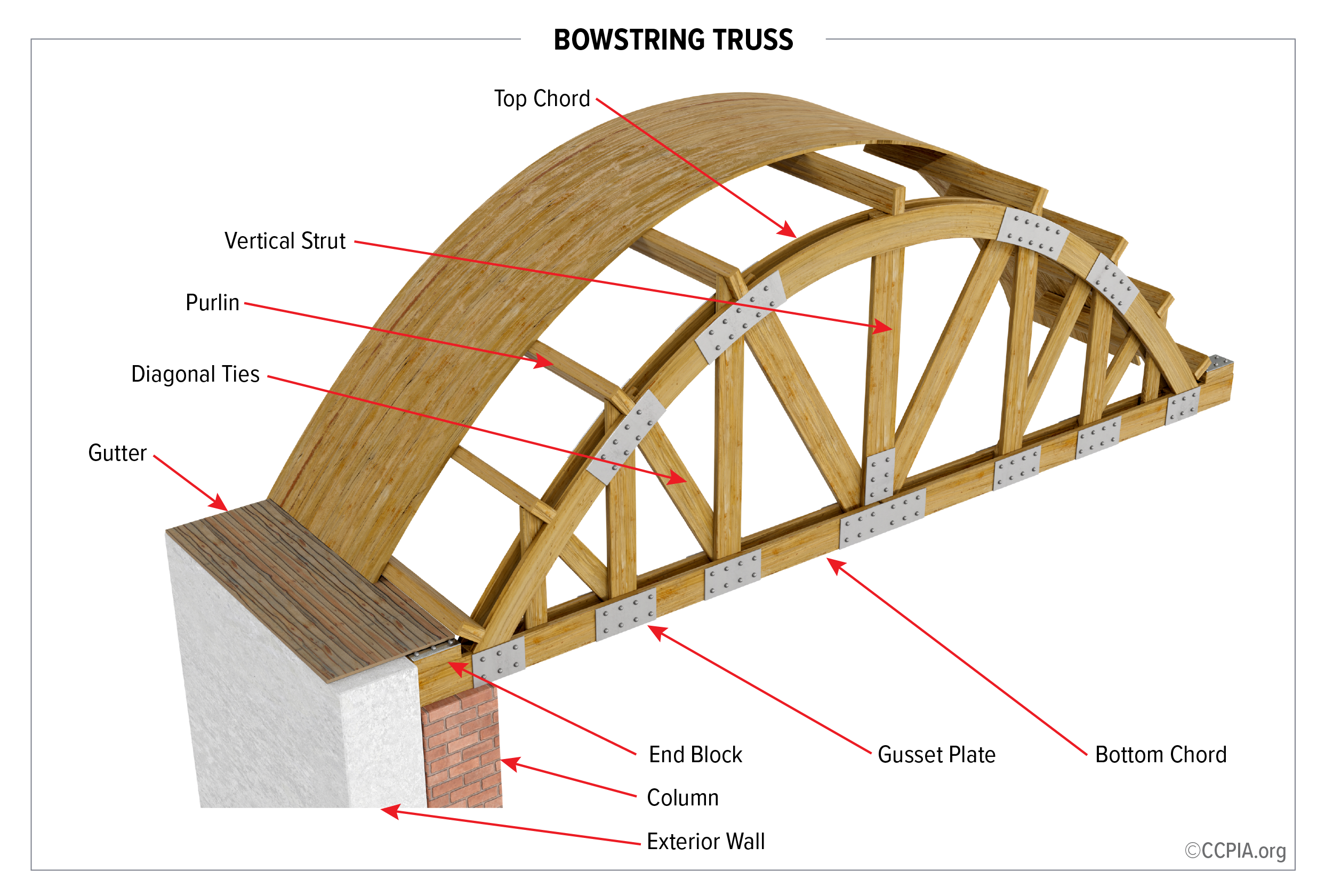

Bowstring Truss

History

Trusses were first used by the Greeks in primitive dwellings as early as 2500 BC. These first trusses were built of timbers. Roman architecture expanded on the use of trusses to create a larger span. These spans allowed for larger open interior spaces, which, in turn, created the “great halls.” It was not until 1200 AD that this type of structure got its name. The term “truss” is derived from an old French word “trousse,” which means a collection of things bound together. A truss is a bound or connected collection of structural members.

The history of the bowstring truss dates to a patent issued in 1841 to a self-taught engineer named Squire Whipple for the construction of a bridge. This bridge was one of the earliest examples of construction that used metal instead of wood. This design is still known today as the Whipple Truss Bridge.

The bridge design transitioned to roof design in the early 1900s. This type of roof was very popular between 1900 and 1950, especially in buildings where large, open spans were desired. The types of buildings that incorporate this feature include manufacturing facilities, garages, warehouses, arenas, and roller rinks and ice skating rinks, among others. Again, this truss design provided a flat ceiling with a span of between 30 and 60 feet without any type of interior support, and can be found to span more than 50 to 100 feet.

Design

The bowstring truss is designed with a bottom chord that is horizontal and rests on a stable, solid load-bearing surface. The top chord creates the signature arch. Between the top and bottom chords are a series of vertical struts, diagonal ties, and pinned connections. The span of the truss is determined by the size or thickness of the components used, as well as the height of the truss arch that was created. For example, if the truss is created using 2×12 lumber, it will span a greater distance than a truss created by 2×8 lumber. An arch that is 10 feet high spans a distance greater than one that is only 6 feet high.

The span can also be increased by the number of splices used to create the truss. Most bowstring trusses are created by using two pieces of lumber spliced together. This creates a stronger truss. If the truss requires additional strength, a third or fourth set of lumber can be added.

The bowstring truss is designed to sit on a bearing surface. This surface is what supports the entire structure. The surface is often a pilaster built into a masonry wall. A pilaster is also known as a column. The pilaster or column can be easily identified by its projection away from the straight wall. This projection could be on the interior or exterior of the building. It is the use of the pilaster that gives the first indication that a bowstring truss system is present.

Pilaster was built into the wall to serve as the bearing point

The bowstring truss can be spaced along a wall up to 30 feet. The wide spacing between the trusses can be filled with purlins. The purlins create a point of attachment for the roof decking, as well as adding stability between the trusses. Not all bowstring trusses are wood. Some can be cast iron or steel.

Issues

Regardless of the type or style of the truss, all trusses have a potential for failure. The majority of failures are a result of a failure at either the top chord or the bottom chord. If a truss buckles or overturns, it is because of the failure of an adjacent truss or its bracing. There are many documented issues or failures of bowstring trusses. These issues range from partial failures to total collapse. Here are a few examples of these failures.

Trusses Placed Behind Parapets

The bowstring truss is often placed behind a parapet wall. This wall rises perpendicular to the trusses and thus creates a well or a trough between the base of the truss and the exterior wall of the building. This trough typically has drainage designed into it. This could be built-in drains in corners, scuppers through the side of the parapet, or gutters at the ends. Any failure of the drainage system will result in the opportunity for large amounts of water to pool or pond. The weight of this water pressing against the parapet and the bearing point of the truss can cause the wall to lean outward and the truss to separate from the bearing point. The separation can cause a total collapse of the truss system and a catastrophic failure of the roof system.

Fires

The bowstring roof is a dangerous roof for firefighters to navigate. The wide spacing between trusses does not provide a solid roof deck for firefighters to stand or walk across. The 10 feet or more of spacing between the trusses means that if one truss were to fail, there is a possibility that the two adjacent trusses will also fail. This could open up as much as 20 feet or more and cause the roof to collapse.

An advantage of having this type of truss construction is that the roof structure is exposed and open. This provides the firefighters with a direct line of access from under the roof at the interior of the building. A high-powered hose can thoroughly access the trusses, roof deck, and any other exposed parts of the building and prevent the spread of the fire. If the trusses are enclosed and the ceilings are not exposed, the firefighters will not be able to see the location of the fire or access the enclosed space.

Many local jurisdictions have made it a requirement to always make the trusses exposed or have a placard placed on the building to indicate that there are trusses present. This simple placard on the exterior of the building will alert the firefighters of the presence of a truss roof so they can proceed with extreme caution.

Material Failures

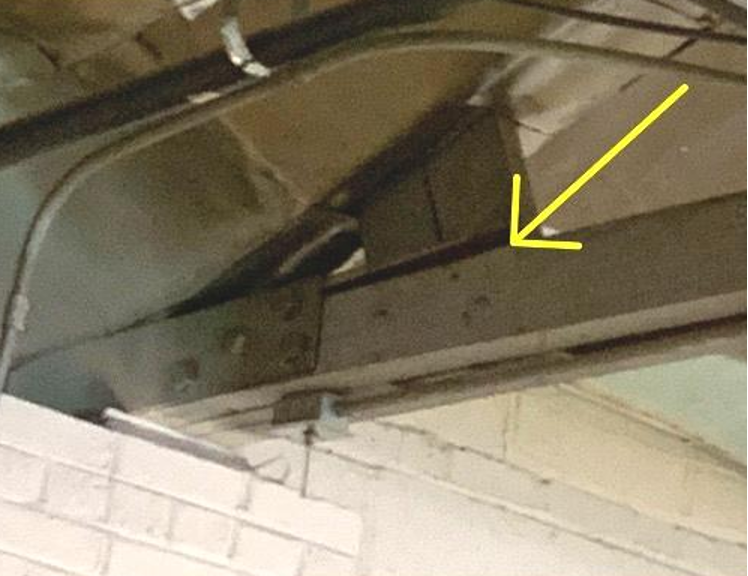

Most bowstring trusses are in buildings built before the 1950s. These trusses were often built on the job site by expert carpenters. They relied upon the experience and materials of that period. The gusset plate, which is the plate that connects all of the elements of the bowstring truss, might be made of cast iron, steel plate, or wood. A wooden gusset can compress or crack over time. A steel or cast-iron gusset can rust or fatigue. The bolts and fasteners can rust and fail. Finally, the wood can decay and deteriorate from moisture or fall through the stresses placed upon it by the loads of the building.

Bolted gusset at the bottom chord

Split wood at the gusset near the bearing point

Maintenance

The most important maintenance a building owner can do is to have routine inspections performed on the trusses. This inspection is recommended at five-year intervals. Beyond the inspection, the maintenance staff, contractors, and employees should never cut, modify, or hang equipment from the trusses. These conditions can not only manipulate and damage the truss but also change the way the truss carries the load of the building, causing eventual failure.

Note: The hanging of heavy objects from the bottom cord of the truss is the most common issue an inspector can identify.

Debris must always be kept clear of the roof drains and gutters. This will help prevent any standing water from pooling on the roof or against the parapet. A pool of standing water on a roof that is 1 inch deep and 20×20 feet wide can weigh 2,000 pounds.

Here are some additional tips an inspector may give to a client:

- Look for signs of water staining or efflorescence on the trusses or on the masonry supporting the trusses.

- Check the trusses for deformities or changes in the smooth arch along the top chord.

- Look for cracking anywhere on the wood truss or masonry wall supporting the truss.

Inspection Tips

Commercial building inspectors are not required to provide engineering services but should be able to observe the conditions that are present during the inspection. This includes the physical state of the bowstring trusses. One of the best ways of achieving this is to thoroughly examine each of the bow trusses for damage.

NOTE: Commercial property inspectors should not walk on bowstring truss structures. This can be very dangerous.

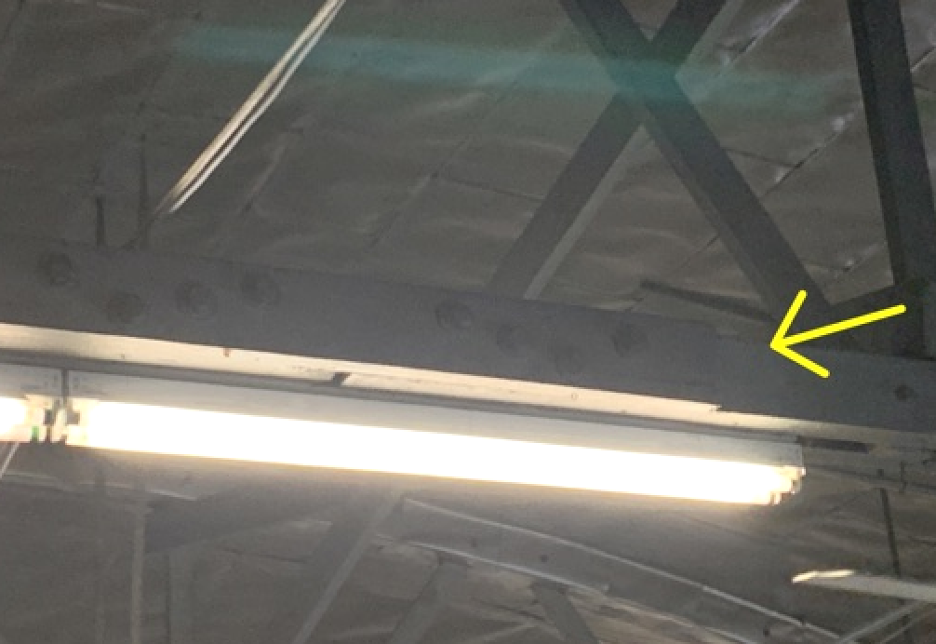

Most bowstring trusses can be easily identified through the arched or barrel-type roof. Some buildings may have been modified to incorporate a flat roof. These buildings do not show the arch, and the only sign that a bowstring may be present is pilasters or columns. The modified flat roof design can also obscure the truss from the interior. Other buildings may have high exterior walls or tall parapets. These buildings do not provide any visible clues from the ground as to the actual type of roof design.

When inspecting the bowstring trusses, the bottom chord should be resting on the bearing point and be free of any damage. This damage could include crushing at the bearing point or cracking or deterioration of the wood. The bottom chord should be straight and level or parallel to the floor.

The top chord should have a consistent arch and be free of any bellies or deflections. A belly or deflection at the top chord may be an indication of stress and structural issues. Standing under each truss and looking directly up from the bottom should show each of the trusses as a straight line. Any twisting or variations from straight may also be an indication of a structural issue.

Each of the gussets or fastener plates should be free of visible damage, and all of the large fasteners should be present. It is beyond any expectation that an inspector would be able to see every screw or nail, but the large bolts, often over 1 inch, should be present and visible.

Each of the columns or pilasters should be plumb and straight to the walls. These structural elements should be free of damage and cracking. Any damage or cracking should be noted on the inspection report.

Conclusion

The bowstring truss is a design that has been used across North America for over 125 years. These roof systems have been used in every sector of building design. These buildings can include manufacturing, service, institutional, and warehouse spaces. While the design is solid and founded in good engineering practices, this type of construction has its issues, and failures have been well documented. Inspectors need to be familiar with this type of structural design and know what to look for when providing commercial property inspections. Most importantly, inspectors should take photos of the trusses and document any issues that might be present.

Article Written By: Rob Claus, CCPI

Additional Resources for Commercial Property Inspectors:

- Fenestration: Exterior Doors Article

- Perspectives of ComSOP 6.5.2 Exterior Elements Video

- Commercial Property Exterior Inspection at InterNACHI’s Pennsylvania House of Horrors® Video