Terms You Should Know:

- Working space: The front clearance, side clearance, and height clearance requirements for electrical equipment that provide a safe area for maintenance, inspections, and other work.

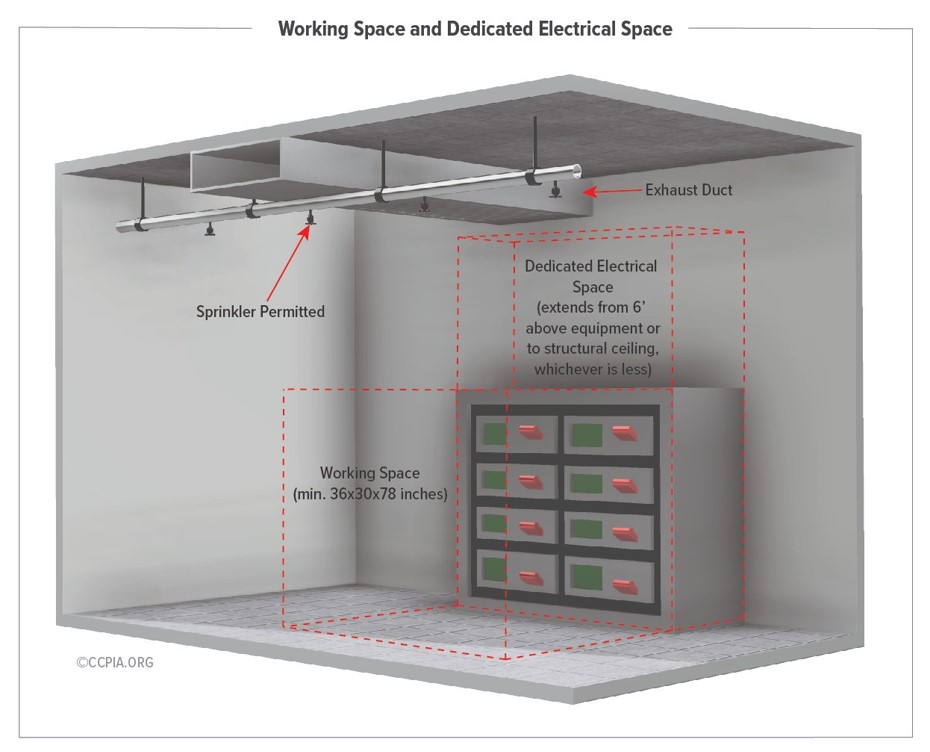

- Dedicated space: The space equal to the width and depth of electrical equipment in addition to the space extending from the floor to 6 feet above the equipment or structural ceiling.

The International Standards of Practice for Inspecting Commercial Properties (ComSOP) states that the inspector should report on the lack of accessibility or working space for electrical panels and gear that would hamper their safe operation, maintenance, and inspection. Many jurisdictional and code requirements also outline requirements for adequate access due to their importance for safety.

Note that sufficient working space is relative to the clear space in front, between, and above electrical equipment. There are different requirements for a single row of equipment, electrical rooms, rack rows, and foreign systems. In some cases, there will be a name plate on the electrical equipment that states the clear space requirements.

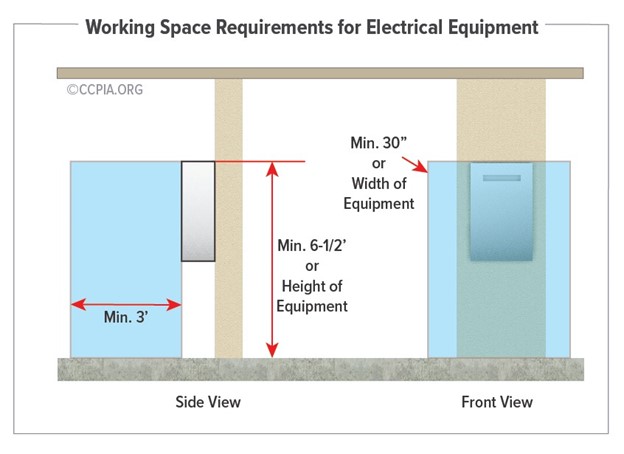

The following clearances are specific to a single row of equipment located anywhere in a commercial building, including public spaces such as hallways, corridors and open rooms. The clearances are often referred to as the 36x30x78 Inches Rule to summarize the clearances.

- Front clearance: There should be a minimum of 3 feet of clearance at the front of all electrical equipment, including panelboards, switches, breakers, starters, transformers, etc. Note that all panel doors and access doors must be able to open a minimum of 90 degrees.

- Side clearance: There should be a minimum of 30 inches of clearance from the sides of all electrical equipment, but in no case less than the width of the equipment itself. This is referred to as the side-to-side working space.

- Height clearance: The minimum headroom in front of the equipment is 6½ feet, or the height of the equipment itself, whichever is greater. At no point can this be less than the height of the equipment.

In all cases, these rules were established as requirements so that an electrician would be able to jump clear or fall away from a piece of equipment in the event of a mishap, instead of being trapped.

Electrical Rooms and Racking

In many commercial facilities, electrical equipment rooms have rows of equipment operating at more than 150 volts to the ground. The aisle(s) between pieces of such equipment, with live parts on both sides of the aisle, must be at least 4 feet wide. If the voltage exceeds 600, clearance must be increased even further.

The following table is based on the NEC® 110-34 and summarizes the clearance requirements for common voltages for rows of equipment.

| Voltage | Minimum Depth | Opposite from Grounding Surface | Opposite from Live Part |

| 0 – 150 | 3 feet | 3 feet | 3 feet |

| 151 – 600 | 3 feet | 3½ feet | 4 feet |

| 601 – 2,500 | 3 feet | 4 feet | 5 feet |

| 2,501 – 9,000 | 4 feet | 5 feet | 6 feet |

Electrical Room

Switchboards and gear rated over 1,200 amps and over 6 feet wide require an exit at each end, or a doubling of the required front working space, so that a person will not be trapped behind arcing electrical equipment. If a second exit is not provided, the clearance from the table above must be doubled.

Dedicated electrical rooms should never be used for storage, and a clear path of travel should be maintained for emergency egress. Oftentimes, these rooms become a catchall for everything from spare light bulbs to office supplies. Inspectors should report on relevant findings in their report.

Foreign Systems

A foreign system, which is any system that is non-electrical, may not be located in the dedicated equipment space. The dedicated equipment space is commonly referred to as the equipment footprint (the space equal to the width and depth of the equipment). The dedicated equipment space also extends from the floor to a height of 6 feet above the equipment or to the structural ceiling, whichever is lower.

An example is a 30-foot-high ceiling in a warehouse, with the electrical panel located on an exterior wall. The panel is mounted 6 feet above the floor. Since the clear height of the ceiling is 30 feet and there is no ceiling above the panel, then 12 feet or above (6 feet for the panel and another 6 feet for dedicated space) may allow any other systems to be mounted on the wall or be located above the panel.

Another example is a 10-foot-high room. The panel is mounted on the wall 6 feet from the ground. That would leave 4 feet to the ceiling. This room has a sprinkler system. A sprinkler system may be located so that it sprays into the dedicated space, so long as the piping is not in the space. Additionally, if there is any equipment installed over electrical equipment that may leak, regardless of height, it must have a secondary drip pan installed to collect any moisture before it can come into contact with the electrical gear. The electrical system and gear must be protected from any moisture-related damage.

Conclusion

Clearances are based on the safety of those who have to service the equipment. The inspector has to be cognizant of the entire system and note any deviations from these rules. The inspector should also not enter or access spaces that may not meet these minimum requirements. Inspector safety should be the first priority.

Article Written By: Rob Claus®

Additional Resources for Commercial Property Inspectors: