A hanging gas furnace is a cost-effective alternative to a central heating system in warehouses, garages, loading docks, and manufacturing environments that typically have high ceilings and open floor plans, as they do not take up floor space. Commonly referred to as hanging units, under most conditions, they do not require much maintenance, and have a service life of more than 25 years.

A hanging gas furnace is a cost-effective alternative to a central heating system in warehouses, garages, loading docks, and manufacturing environments that typically have high ceilings and open floor plans, as they do not take up floor space. Commonly referred to as hanging units, under most conditions, they do not require much maintenance, and have a service life of more than 25 years.

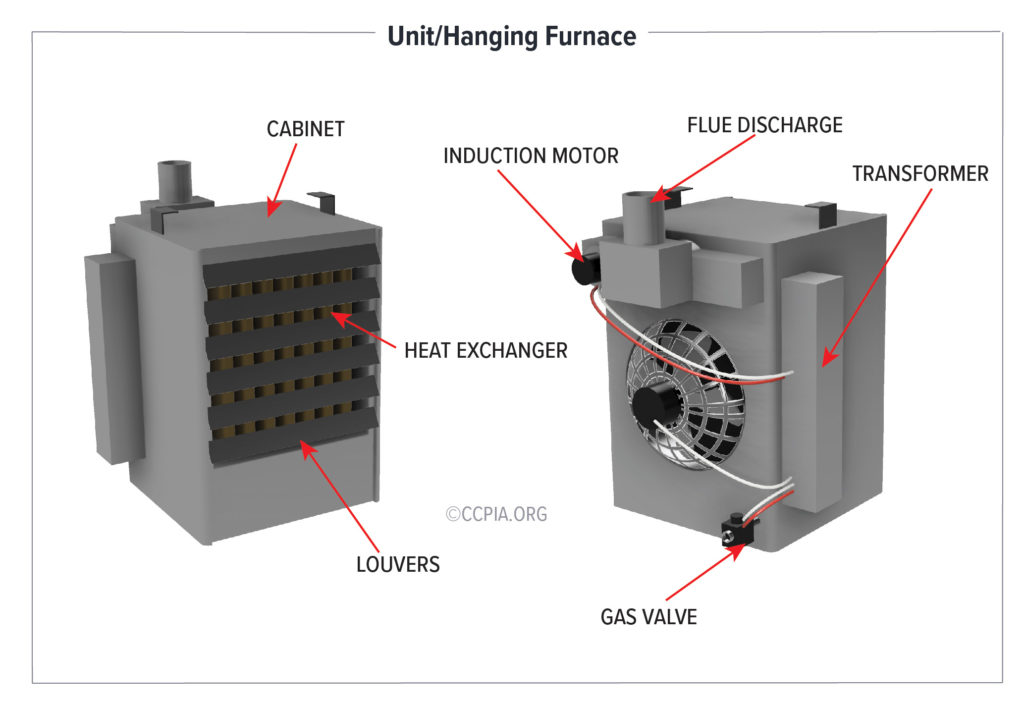

The hanging gas furnace uses a series of heat exchanger cells located in a common cabinet. This cabinet is hung up near the ceiling in the best location to provide heat to the desired space. Within the cabinet, there are gas burners or jets, a circulation fan, a gas valve, and an igniter, in addition to directional louvers to control where the heated air flows.

Common Concerns for Hanging Gas Furnaces

Commercial property inspectors should perform a visual assessment of hanging units, and verify that they are in good working condition using their thermostat. Inspectors are not required to operate units found in the “off” position.

Hanging units are typically installed near the ceiling. The installation height may pose an issue for the inspector attempting to access the unit. Some inspectors may choose to use binoculars, an advanced zoom camera, or a very tall ladder to access the unit and read the label plates. Note that some large buildings or spaces may have several units. Each unit will have its own thermostat.

There are several things to look for when inspecting hanging units. Most are a self-contained piece of heating equipment that requires connections only to the energy source. These units are installed in the spaces they are intended to heat and do not use ductwork to distribute heat. Any field additions or ducting should be noted as an issue in the inspection report.

The most common failure of these units is to the gas valve and igniter, and damage to the flue pipe. Gas valves routinely fail, and so does the igniter assembly. These are not expensive repairs; they can often be replaced by most maintenance technicians. The flue pipes extend upward through the roof. These are at least partially exposed to the elements, and this exposure can cause rust and corrosion. Inspectors should also note if any items impede the flow of heats, such as columns and ductwork.

In summary, inspectors will find hanging gas furnaces installed near the ceiling in large and open spaces, such as warehouses and manufacturing environments. The inspection of these units should include identifying and activating the thermostat. The thermostat should initiate the ignition and burners. A heat sensor should activate the circulation fan, and heat should be distributed through the exchangers. Each unit should be operated during the inspection, and visible issues should be noted. Use CCPIA’s Hanging Gas Furnace Inspection Checklist for help during an inspection.

Article Written By: Rob Claus, CMI®

Additional Resources for Commercial Property Inspectors: