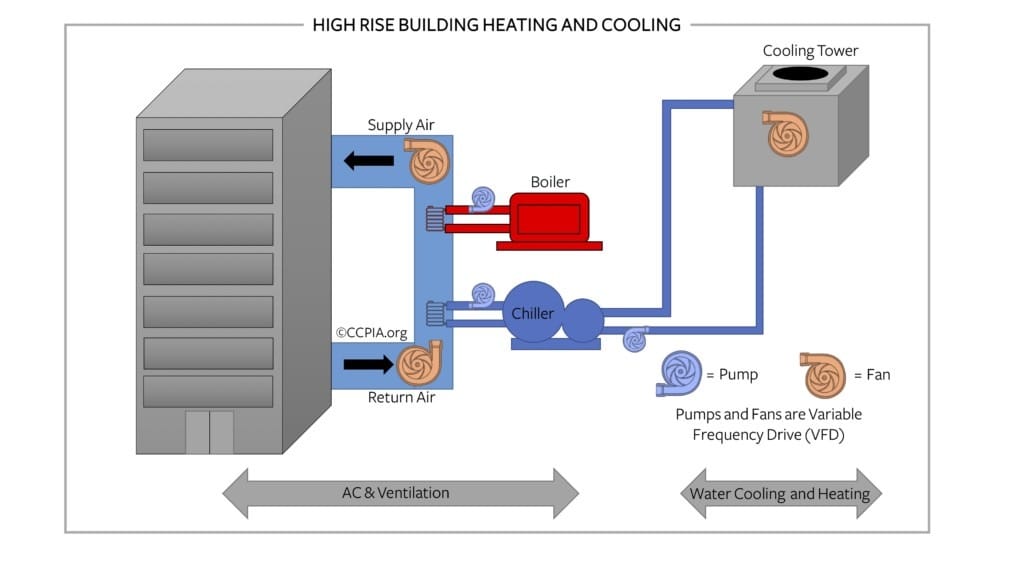

Central plant systems typically consist of components to provide chilled water for cooling, and use a boiler for heating water. Boilers typically operate at 17º F to 200º F, although most units that are manufactured currently are computer-controlled and may operate at as low as 100º F, depending on the exterior temperatures and the heat demand.

Heat Mode

In heat mode, the boiler heats the water, and the water is pumped to the air handler, where the blower fan forces the air past the finned heating coil. Heat is given up from the coils and transferred to the air. The cooled water is then pumped back to the boiler, and the process is repeated.

Air Handlers

The air handler or handlers of a central plant system typically contain a single fan or blower, and separate coils and piping for heating and cooling. The air handler usually connects to supply and return ducts. Return air (and usually some outside air) is passed over the heating and/or cooling coils and sent to the individual areas by the supply ducts. Occasionally, the return air duct may be the ceiling cavity above the ceiling and adjoining floor. Some systems may be considered dual-path, where heating and cooling coils are run parallel, and the air temperature is controlled by room thermostats and in-duct temperature sensors.

Cooling Mode

For the cooling side, two methods are used to condense the refrigerant in chillers: the condensers can be air-cooled or water-cooled.

Air-Cooled Condenser

A typical air-cooled chiller uses fan blades to draw ambient air over a finned coil to condense the refrigerant. It may contain one to five compressors.

Chilled water systems with air-cooled chillers have lower initial installation and maintenance costs, as they do not require a condenser water cooling system and cooling tower. Air-cooled chillers are used when it is not practical to use a cooling tower, such as when the water supply is low or poor-quality.

The refrigerant condensing temperature in an air-cooled chiller is dependent on the ambient or dry-bulb air temperatures, which must be below 95º F. Air-cooled chillers are available in package units of up to 500,000 tons.

Water-Cooled Condenser

A typical water-cooled centrifugal chiller uses recirculating water from a cooling tower to condense the refrigerant. Water-cooled chillers are more efficient and have lower operating costs. In a water-cooled chiller, the refrigerant condensing temperature is dependent on the water temperature and the volume of water entering the condenser.

The refrigerant condensing temperature in a water-cooled system is significantly lower than in an air-cooled system, and a water-cooled condenser is typically cheaper to operate. An inspector may find many gauges on this type of system that measure and record the pressures, temperatures, and electrical measurements, all of which should be documented during the inspection. Water-cooled chillers are commonly available of up to 3,000 tons. Specialty units of up to 10,000 tons are also available.

Cooling Tower

Water is pumped into the cooling tower from the chiller and either sprayed into the air inside or discharged onto media pads, where heat is then transferred into the airstream by evaporation. The cooled water is then pumped or gravity-fed back to the chiller, where the heat absorption process is repeated.

Refrigeration Cycle for a Water-Cooled Chiller

Chilled water systems circulate cold water of between 40º F to 45º F through the air to water air handlers. As the air is cooled and passed through the finned coil, it gives up heat to the water. Most chilled water systems are designed so that, at the maximum air-conditioning load, the water leaving the coil has been heated 10º F.

Liquid refrigerant takes on heat from the building’s return water flowing through the evaporator or air handler and changes it to a vapor. The vapor is drawn into the compressor, and its temperature and pressure are raised. The compressor raises the temperature and pressure to the level required by the condenser (typically, 97º F). The gas is then discharged into the condenser, where it is cooled by either the air-cooled condenser fan or by water from the cooling tower, and then changes back into a liquid. The cycle then repeats.

Additional Resources:

Commercial Property Inspection Technical Class (Live)

Hiring Independent Contractors

Repair/Replacement Cost Estimate Clauses