An air curtain unit (ACU), also known as an air door, is a mechanical device used to create an invisible barrier between two different environments. It generates a controlled stream of air and projects it across the entire height and width of an opening to create a seal. This airflow seal separates two environments without limiting the access of people or vehicles. ACUs are used to reduce the amount of air and contaminants infiltrated and exfiltrated through an opening, and are typically installed above doors and windows.

How ACUs Work

Heat transfers occur between two different environments because of the second law of thermodynamics, which states that heat flows naturally from an object at a higher temperature to an object at a lower temperature. Hence, the temperature and pressure differences between two sides equalize and convection occurs, allowing warm air to escape through the top of a doorway and be replaced by cold air.

Advantages of ACUs

An ACU increases a commercial property’s energy efficiency and savings by:

- minimizing the air exchange at an opening. It reduces the amount of air transferred from the inside to the outside of a conditioned space;

- reducing the amount heating and cooling needed by a central plant. This can also increase the lifespan and functionality of a heating system;

- reducing the amount of CO2 emissions produced; and

- reducing energy expenses.

Additional benefits of an ACU include:

- deterring pests and insects;

- limiting the migration of airborne pollutants, including dirt, dust, odors and fumes;

- maintaining employee and customer comfort;

- increasing visibility at openings;

- eliminating ice and fog in cold-storage areas; and

- maintaining the usable space around a door.

ACU Components and Their Functions

ACUs consist of five main parts: a control, cabinet, fan, motor, and filter. The control is the air curtain’s activation system. The type of activation system depends on the type of motor and heating and cooling requirements. ACU controls can be fully customized to suit the application. Examples of activation systems include automatic, remote, and thermostat-incorporated. Automatic activation controls allow air curtains to automatically activate when a door opens. Remote activation controls allow users to run an ACU simultaneously when a door opens or closes, or allows the user to manually turn the unit on and off. Thermostat-incorporated activation controls are typically tied to a computer-controlled system to regulate heating and cooling requirements. If a commercial property inspector observes that the air curtains activation system, or overall operation, isn’t operating correctly, he should recommend that the client contact the ACU manufacturer or a licensed electrician.

The air curtain cabinet encloses the device’s motor(s), fan(s), heater, and other mechanical components used for operation. Galvanized steel, stainless steel, and aluminum are the most common cabinet materials, but plastic is also available. The cabinet material depends on the ACU’s application. Commercial property inspectors should inspect ACU cabinets for corrosion and other physical defects, such as dents and cracks.

ACU Fans

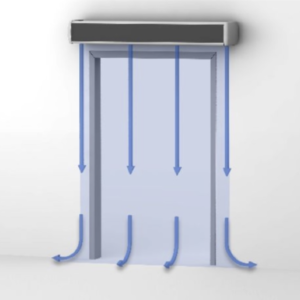

ACU fans are either direct-driven or belt-driven. The most common fan installation is downward-facing and mounted above an opening. This generates a horizontal air discharge from the top to the bottom of the opening. However, a fan can also be installed to vertically discharge from one side to another, or to horizontally discharge from the bottom to top. Properly operating ACU fans are powerful enough to generate air flow that projects across the entire opening. For instance, an ACU installed above a doorway should generate a jet of air that can reach the floor.

ACU Filters

ACU filters protect the motor and fan from harmful debris and contaminants. Not all ACUs have filters, but commercial property inspectors should recommend that property owners and managers properly maintain their ACU filter. Clogged filters can reduce the fan’s airflow and the device’s overall efficiency. Additionally, some air curtains are heated and have a coil. Commercial property inspectors should be careful when inspecting an air curtain, as the ACU may be hot to the touch.

Types of ACUs

There are two types of air curtains: non-recirculating and recirculating. A non-recirculating unit discharges air by drawing air into the unit directly from the surrounding environment. A non-recirculating unit is used primarily for temperature and insect control.

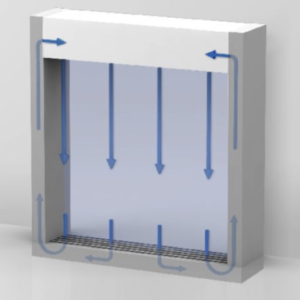

A recirculating unit is more efficient. It typically emits air from a discharge grille on one side, collects it through a receiving grille on the opposite side, and returns it through ductwork to the discharge grille. This system is recommended for doorways that are opened for extended periods of time with a high rate of traffic, like supermarkets and store entrances. It is not intended for insect or pest control.

Air Curtain Unit Applications:

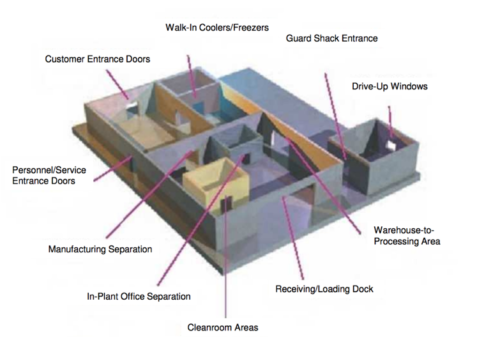

- Exterior environmental separation provides a barrier to an exterior door from undesired infiltration and exfiltration at an opening due to wind, draughts, and temperature differences. These installations are typically found at loading docks and transportation terminals.

- A barrier between interior rooms connected by a shared opening is installed to prevent the entrance of unconditioned air and the exit of conditioned air from one room to another. These installations are typically found at stores and factories. Heated units must always be installed at the interior.

- Insect control provides a barrier at the exterior of a space to prevent the entry of insects and other pests. ACU installations of this type are a common requirement for facilities that produce, process, and/or serve food products.

- Cold storage provides a barrier against the loss of refrigerated air through openings. An exterior installation is required when used over a freezer door because fans tend to gather moisture and freeze, eventually collecting ice and causing the unit’s efficiency to decrease.

- At ovens, ACUs provide a barrier against the loss of heated air through openings. An ACU is usually installed horizontally over the oven’s opening and is angled slightly inward to prevent hot air from escaping.

- At food and hospitality facilities, ACUs provide a barrier to prevent contamination and unwanted conditioned air transfer. Commercial property inspectors may observe ACU installations at coolers and cold storage areas, hotels, the drive-through window at fast-food restaurants, and at the entrance of walk-in restaurants.

- At industrial and distribution centers, ACUs provide a barrier at large buildings that are exposed to the elements throughout the day. ACUs can be used to regulate internal temperature for food safety, or aid with employee comfort in areas that are prone to wet and/or cold weather.

Code Requirements

According to the U.S. Department of Energy, commercial buildings are required to install vestibules on primary entrance doors leading to and from spaces 3,000 square feet or greater. However, the 2015 International Energy Conservation Code (IECC) published by the International Code Council (ICC) announced that air curtains can be considered an alternative to vestibules.

Summary

In summary, air curtains units are installed at commercial properties to mitigate the transfer of conditioned and unconditioned air at structural openings, and to reduce the entry of contaminants, such as insects and airborne pollutants. ACUs can help property owners improve their building’s energy efficiency, and their customers’ and employees’ comfort. Commercial property inspectors may see ACUs installed for a wide range of applications. Inspecting air curtain units is beyond the scope of the International Standards of Practice for Inspecting Commercial Properties (ComSOP), but inspectors may choose to exceed the ComSOP and offer their insights and observations on the condition and performance of the unit. The inspector should refer the client to the unit’s manufacturer or a licensed electrician to assess and assist with any needed repairs or upgrades.