Concrete masonry blocks with an architectural or rough stone surface are called split-face blocks. The face of these blocks has an irregular, rough texture, as if the surface of the block had been hand-chiseled away. In fact, the block is typically formed using a slurry of loose aggregate that is poured into a block form that gives it a hand-hewn appearance.

Split-face blocks are popular because their installation uses the same principles as standard cinderblocks, yet their exterior finish is more aesthetically pleasing because it looks like natural stone. These pre-formed blocks allow a building to be erected quickly, and they’re usually the most cost-effective option because the structure also serves as the finished exterior.

Defects in Split-Face Blocks

Concrete block and masonry block walls have been a standard in the construction of buildings for centuries. A masonry block wall has a cured, smooth finish. For the most part, the finish is weather-tight. Although concrete blocks have some porosity and can absorb moisture, the smooth finish provides durability. These walls are also easily coated for added protection.

A split-face block, on the other hand, is very irregular and not smooth. Thus, the surface is much more porous than a masonry block having a cured, smooth finish. Additionally, during construction, most split-face blocks are not adequately detailed with flashings and drainage planes. The result can lead to moisture or water intrusion, eventually causing mold growth or compromising wooden structural elements.

Depending on the height of the building, there could be hundreds to thousands of gallons of water trapped in the blocks’ channels. This water has to have the ability to shed.

The following are signs of moisture or water intrusion issues:

- water staining on the block, or efflorescence (a white, salty residue);

- water stains on the walls, trim, or floors; and

- drips from light fixtures or electrical outlets.

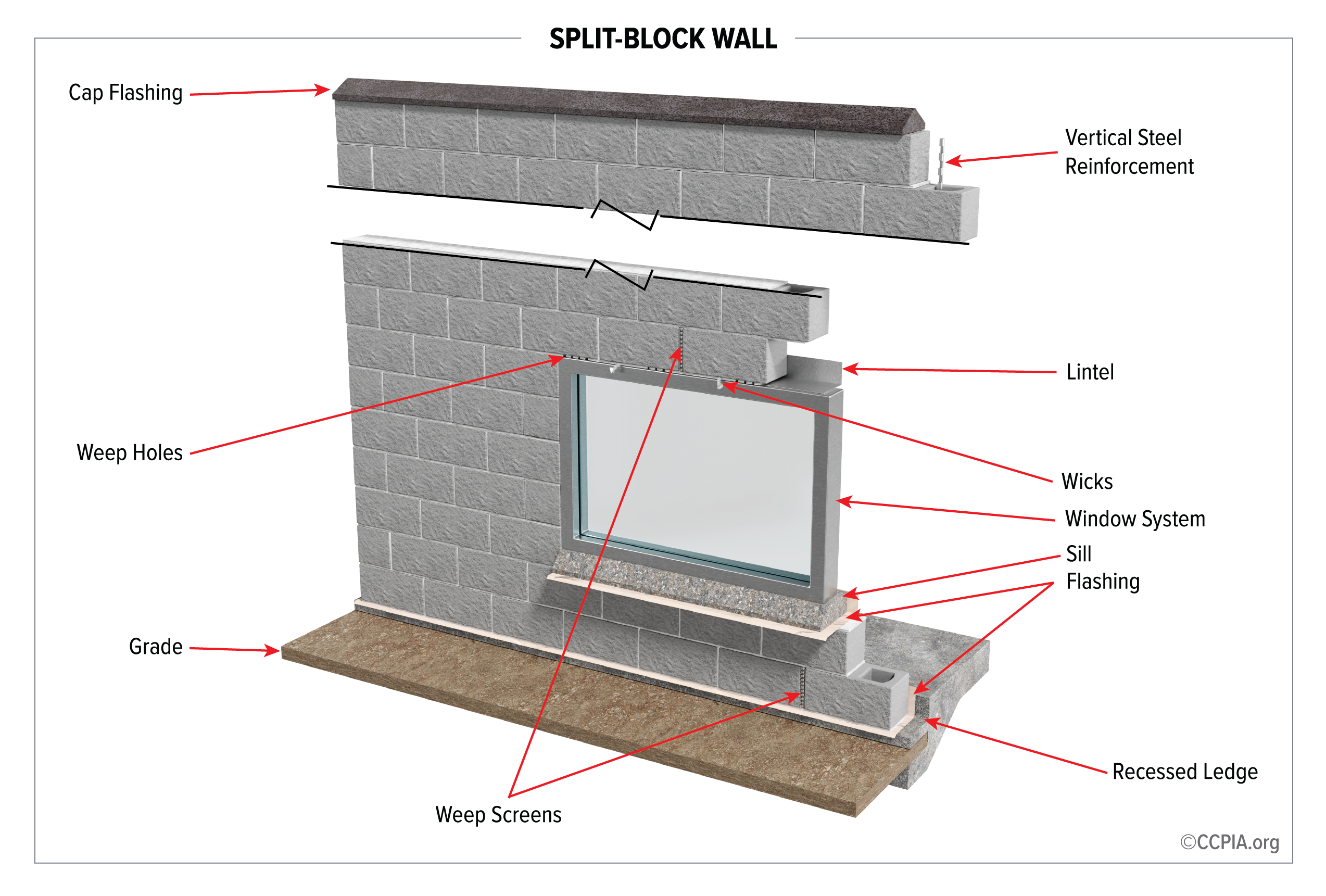

To help remove this trapped water, weep holes are added along the bottom of the split-block walls and above windows in the lintels. Weep screens, which are perforated metal strips, will also help de-water the walls. These screens should be the same depth of the masonry and take the place of an open weep hole. Weep screens should also be added on every floor, with proper flashing at the parapets. The metal strips and weep screens should not be painted or obstructed.

As with any masonry wall, the inspector should also look for potential safety issues, such as broken, chipped, or loose blocks along the wall. This is a common defect found at the top of block walls and at parapet walls.

All of these items should be easily visible during the walk-through survey.

Maintenance and Failure

In general, masonry requires maintenance. However, split-face blocks require more maintenance than standard masonry due to their unfinished texture. The two main measures for preventing moisture problems include applying sealant, and remediating any flashing issues.

Conclusion

Split-face block has drawbacks compared to a standard cinderblock, particularly related to moisture intrusion. Inspectors should assess the interior and exterior walls for unusual staining or efflorescence, as well as flashing and water-control features during their walk-through survey.

Article Written By: Rob Claus, CMI®

Additional Resources for Commercial Property Inspectors: