Assessing electrical panels, or panelboards, is only one part of the electrical portion of a commercial property inspection. Inspectors must fully understand the International Standards of Practice for Inspecting Commercial Properties (ComSOP) to properly and safely inspect electrical panels.

As a ground rule, the inspector should verify that a panel, specifically the panel cover and housing, is not energized before coming into contact with it. One of the best methods for checking is by using a non-contact or limited-contact voltage sensor. Another method is by using the back of your hand to detect any static electricity.

The inspector should also verify that the panel does not lack accessibility or proper clearances (designated as working space), which could hamper safe operation, maintenance, and inspection. The proper clearance for any panel should measure at least 30 inches from side to side, 36 inches from the front, and 78 inches of headroom clearance. Inspectors should note any deviations in their reports. For more information, please read the CCPIA article “Electrical Inspections: Working Space and Safe Clearances.”

Panel Exterior and Door Interior

After the inspector determines that the panel can be opened safely, the condition of its interior can be assessed. Note that the panel cover must open at least 90 degrees. The inspector should look for missing breakers or fuses and open blanks that provide direct access to the space behind the dead front. The inspector should note in their inspection report any openings, since this is a safety issue. It is a relatively simple fix, such as using a knockout or a space filler.

In addition to noting any missing knockouts, the inspector should also look for rust and evidence of burns on the interior and exterior, and around the panel’s perimeter. There should be no access to the panel in order to prevent accidental electrocution or rodent entry. These are also safety issues and should be documented in the report.

Panel Mounting

Panels should be appropriately mounted and securely attached to the wall. Note that concrete and masonry can cause condensation and moisture issues, which can result in the panel developing rust and corrosion. Steel braces or fireproof wood are among the best mounting methods.

Labels

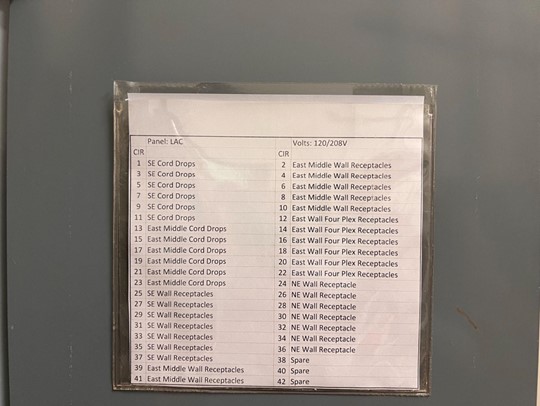

The interior of the panel should display some form of labeling. The inspector is not required to determine whether the labeling and identifiers are accurate; instead, note if labeling is not present, illegible, or incomplete.

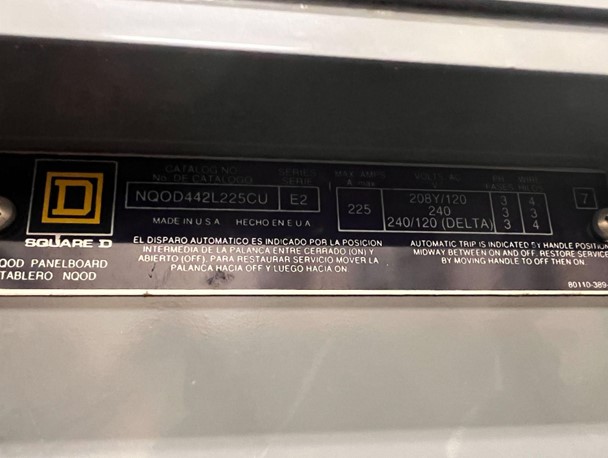

Most commercial panels have two types of labels. One is the panel label and the other is the distribution or circuit labels. The panel label is typically laser-etched or stamped on the panel’s face. This label indicates the amperage, voltage, and the number of conductors serving the panel. This information is unique and specific to each panel. The main breaker for the panel should match the information indicated on this label.

The distribution circuit labels for the breakers and fuses inside the panel should also be clearly labeled and numbered.

Dead Front

The ComSOP doesn’t require inspectors to remove dead fronts since it typically involves dismantling the panel by removing screws. Dead fronts found in commercial applications range significantly in size, weight, and amperage, especially compared to residential systems. Note that panels larger than 200 amps might limit the inspector’s ability to remove the panel safely. The inspector should use their own discretion in determining whether to remove dead fronts.

Panel Interior

Regardless of whether the dead front is removed, the inspector should still be able to provide their client with sufficient information about the condition of the electrical system at the subject property.

The inspector can assess the following items with the dead front in place:

- All the breakers should be of the same panel manufacturer, since some manufacturers have compatibility issues.

- Look for signs of physical damage, rust, corrosion, and overheating, as evidenced by scorch marks.

- There should be of appropriate ties or connections on the 240V circuits, including ties, straps, and wires.

If the dead front is removed, the inspector should:

- Look for grounding and bonding located on the bus bar(s). This should be present in all panels.

- Look for overcrowding. The panel should not exceed 75% the total available capacity or space. This would mean that there must be at least 25% of the panel free and not filled.

- Evaluate the size of the conductors relative to the amperage rated on the fuse or breaker.

- Look for paint. Spray residue from painting can cause a poor connection between the bus bar and the breaker.

Conclusion

In many cases, the inspector’s property-buying client will upgrade or change the electrical system currently present at the time of the inspection before taking over the space due to needs that are different from the current occupant. The key to a quality assessment of an electrical panel is to identify any safety issues and signs of past problems, in addition to taking an inventory of the general condition of the present system. This will help the client determine the best approach in moving forward. Before coming into contact with any electrical system, the inspector should assess their ability to safely proceed, as well as their comfort level. Bringing in specialty consultants or subcontractors is an excellent way to address any concerns.

Article Written By: Rob Claus, CMI®

Additional Resources for Commercial Property Inspectors: